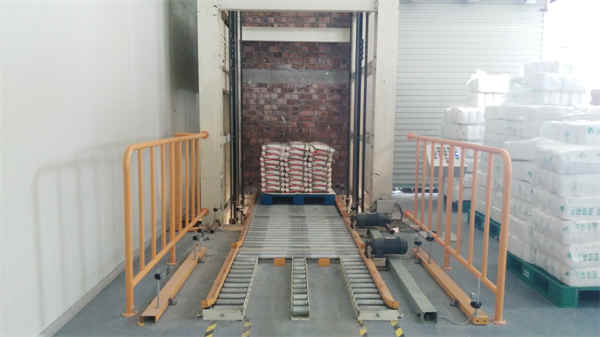

Convoyeur à levage vertical alternatif sans pilote entièrement automatique

Convoyeur de levage vertical entièrement automatique pour charges lourdes sans pilote

Il permet sans arrêt ou le transport alternatif du produit dans un confiné espace. Ce augmenter est caractérisé via sa sécurité, sa fiabilité, excessif efficacité de travail petite zone d'occupation.

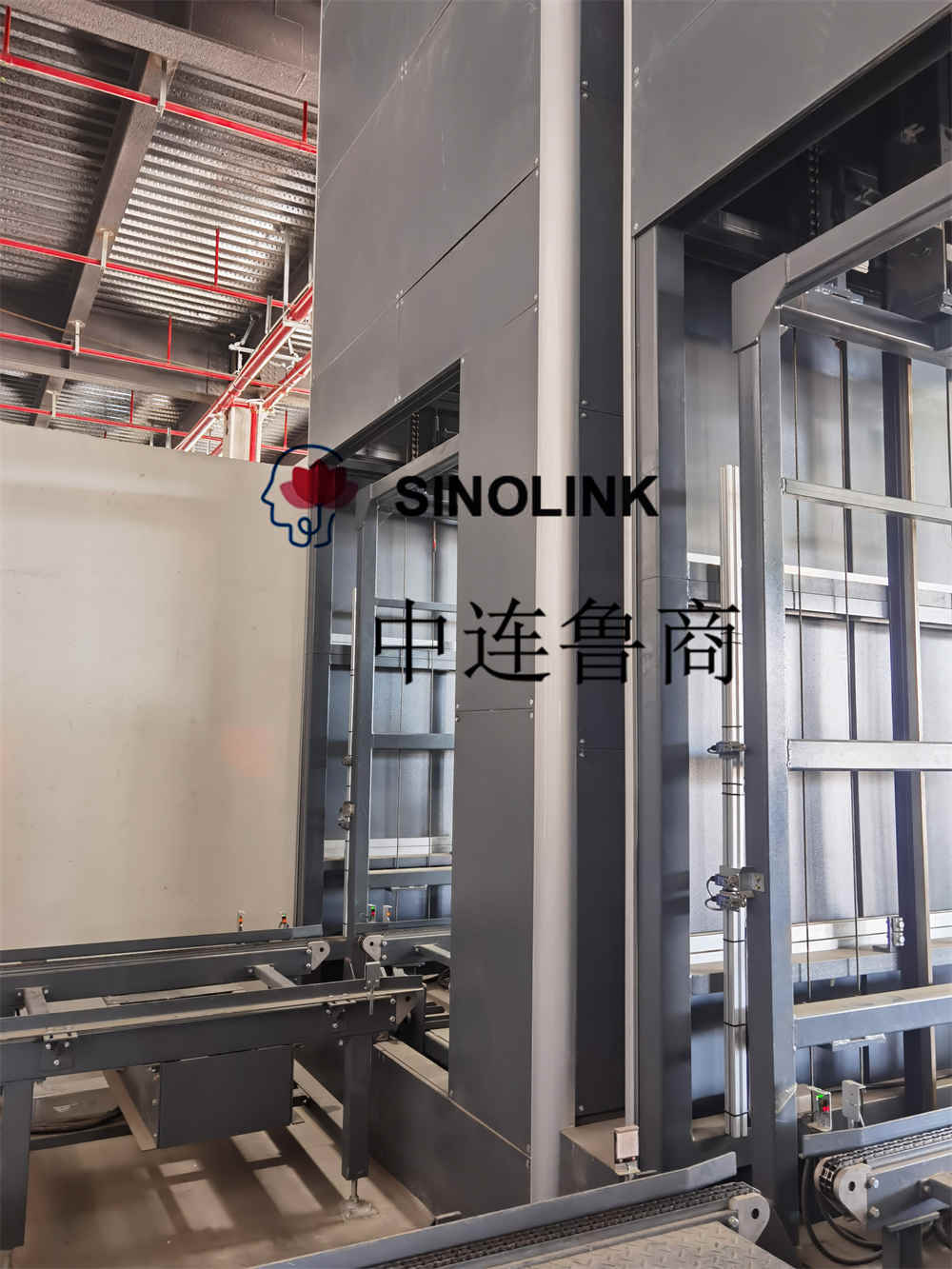

Équipement de levage pour convoyeur à levage vertical alternatif sans pilote entièrement automatique :

Ce convoyeur de levage vertical de type chargement lourd entièrement automatique sans pilote convient au levage vertical de cartons, de sacs tissés, de fûts en plastique et de différentes marchandises.

1 Le cadre fondamental

1 Material: 80*80mm aluminum alloy profiles, linked and assembled by means of screws

two Protective screening: exterior body adopts obvious natural glass

2 Système de convoyage

1 The most important chain makes use of carbon metal 16A-1 curler chain whose pitch is 25.4mm with W-2 bending plates bilaterally.

two The pallet chain adopts unidirectional bending, pitch 25.4mm.

three The pallet makes use of 9269K aluminium profile, the floor is macromolecule plastic

3 Système de conduite

1 The foremost axis makes use of carbon metal with nigrescence treatment, diameter 55mm

two Drive sprocket makes use of 16A-17 duplex chainwheel. Driven wheel makes use of 16A-17 easy chainwheel

three Tension bridle gadget makes use of T208 undeniable bearing housing

four The energy is SEW equipment reducer motor

1 The manipulate software is Taiwan Yonghong PLC programming

two Detecting optoelectronic swap is Omron brand

three The manage cupboard is made of carbon steel

5 Flux de travail du convoyeur élévateur vertical

The product to be delivered is ready on the conveying line related to the elevator. When the photoelectricity detects that the pallet is in place, the PLC troubles a command. The blockading gadget will launch or the conveying line will start, and releases a product to the pallet. When the 2nd product arrive at the ready position, the block will raise or the conveying line stops and starts to wait for the photoelectricity to observe the subsequent pallet, then the PLC programming will trouble a command once more to launch the product.

Exigence détaillée, veuillez nous contacter à tout moment. Nous devons vous aider à fournir le programme le plus optimisé pour vous !

Attd : Ady

Whatsapp:+86 15634865861